© Jens Lehmkühler / U Bremen Research Alliance

Every Gram Counts

How can 3D-printed titanium components be produced in way that minimizes costs and weight?

There are few industries where weight plays as crucial a role as it does in the aerospace industry. The lighter an aircraft, the less fuel it consumes. Researchers from member institutions of the U Bremen Research Alliance have investigated how to reduce the cost and weight with 3D-printing titanium components – and have also developed more environmentally friendly coating systems and customized repair processes.

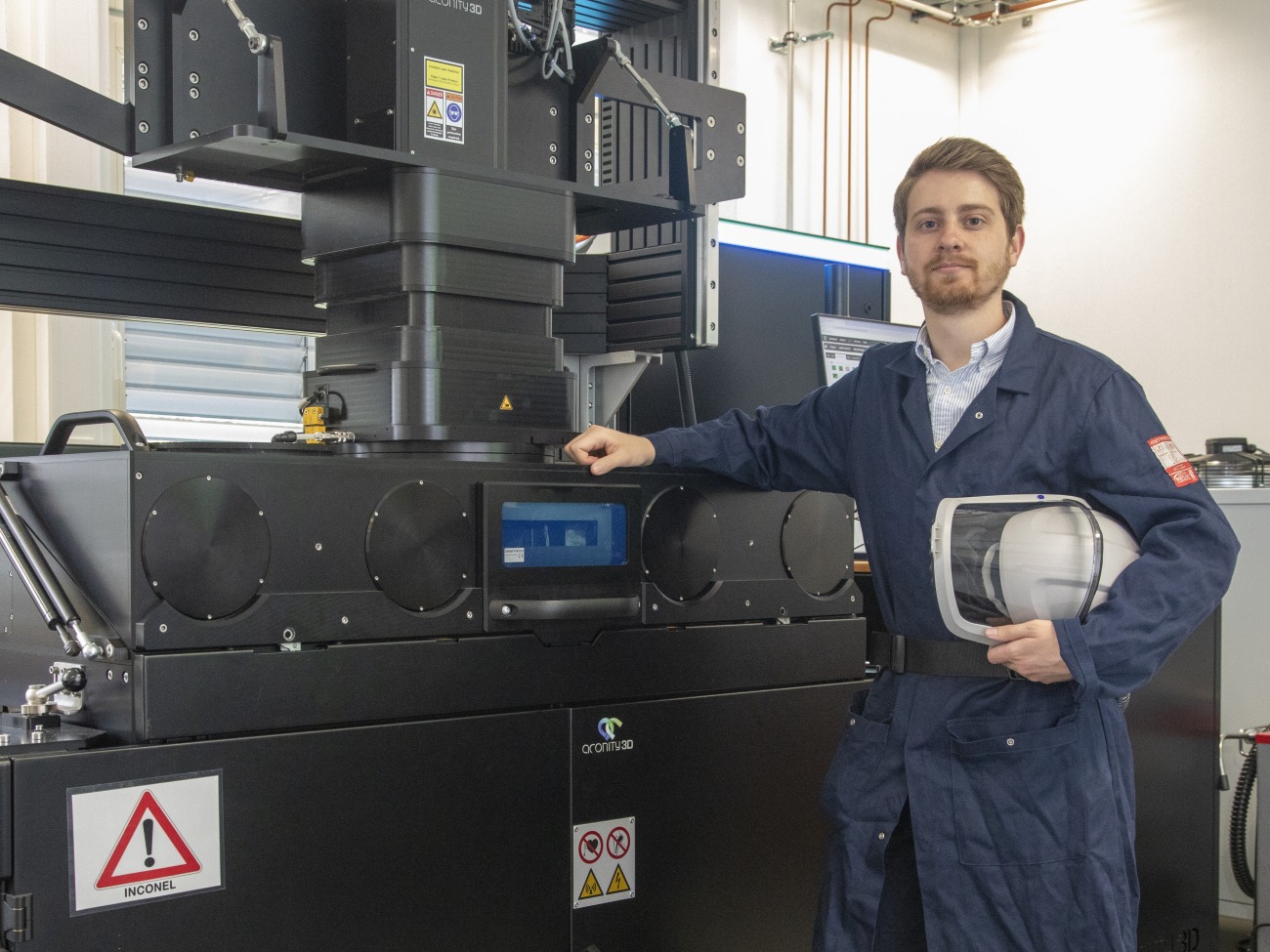

When asked what makes 3D printing so exciting for him, Mika Altmann’s enthusiasm is unmistakable. “Using lasers, we develop materials that cannot be produced conventionally. We are able to determine the properties of a component, its structure, how rigid or flexible it is. This allows us to make changes to the design of even the smallest area within a material.” Altmann adds that the potential of the process is far from being exhausted, which makes it so appealing for him. “Understanding how a particular material behaves, how it can be processed and modified to make it more efficient than previously seemed possible, is crucial for driving developments forward.”

© Jens Lehmkühler / U Bremen Research Alliance

This knowledge is precisely what Altmann, a doctoral student at the Leibniz Institute for Materials Engineering (IWT), a member institution of the U Bremen Research Alliance, wants to obtain. He is involved in the Leibnitz IWT project “Technologies and Repair Processes for Sustainable Aviation in a Circular Economy” (TIRIKA for short).

The project, led by Airbus Operations in Bremen, is funded by the Federal Ministry for Economic Affairs and Energy with around 20 million euros and is a collaboration between approximately a dozen partners from the scientific and industrial sectors. Its objectives are to research various aspects of sustainability in aviation, including metal and plastic recycling, alternatives to hazardous substances, use of digitized processes, sustainable repair methods, and reducing the weight of materials.

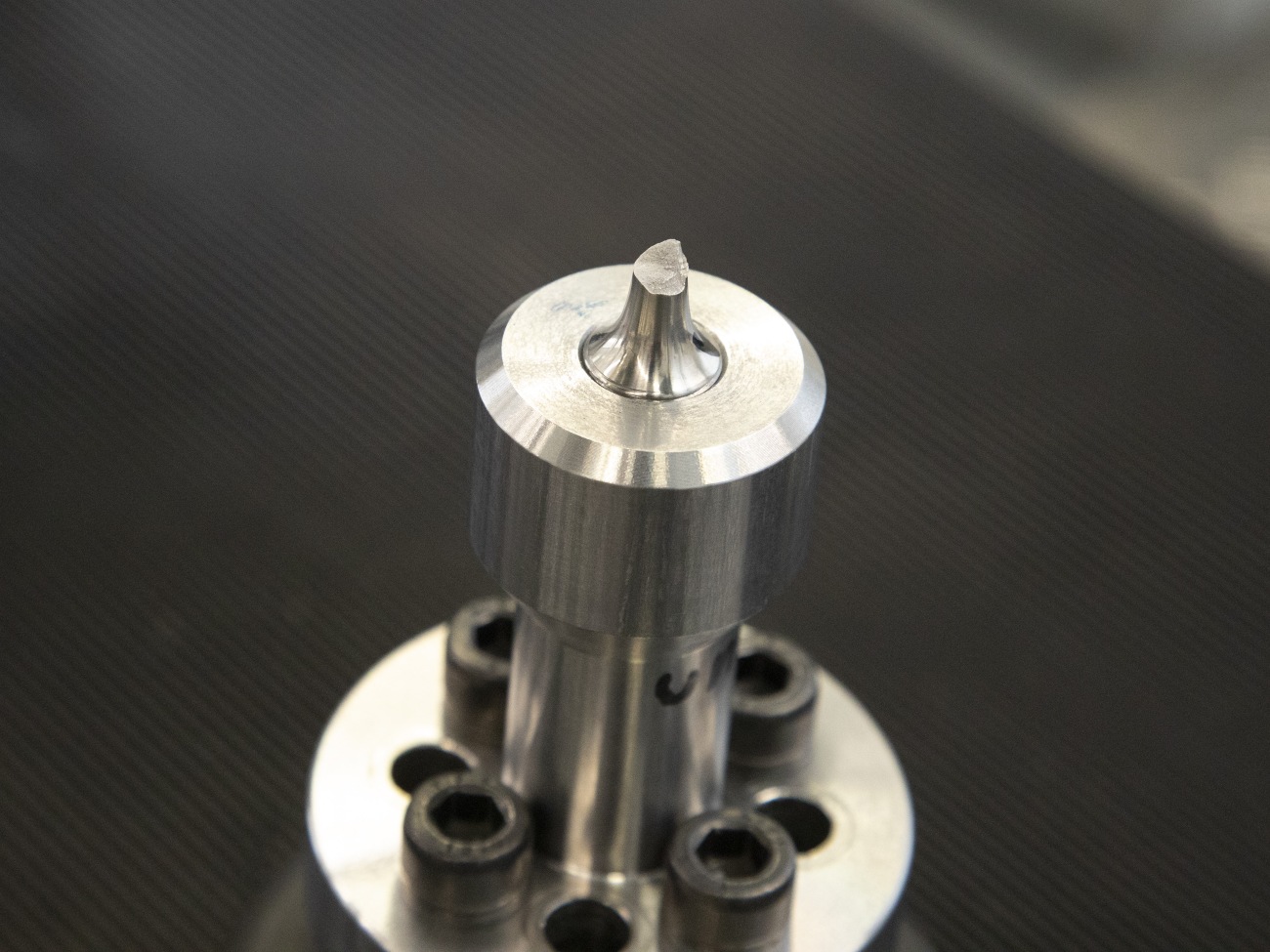

The objective of the Leibniz-IWT subproject is to improve the process of manufacturing 3D-printed titanium components by making these more cost-effective and environmentally friendly. One of the elements in this process involves the use of brackets. These non-safety-critical connecting elements are used in many areas of an aircraft, such as cabin supports. Until now, these have been subjected to a high-pressure heat treatment that combined heat, pressure, and subsequent cooling in order to close the tiny pores of the components that typically occur during 3D printing. This process takes place in a high-pressure cylinder at temperatures of up to 1,400 degrees Celsius and 2,000 bar of pressure using argon, a noble gas. Altman identifies a crucial problem with this, saying, “The process is energy-intensive and outrageously expensive.”

© Jens Lehmkühler / U Bremen Research Alliance

Is it possible to achieve, or possibly improve, the material properties using heat treatment without high pressure? Altmann’s research team is investigating this under the direction of project manager Dr. Anastasiya Tönjes, head of the Lightweight Materials department at Leibniz-IWT.

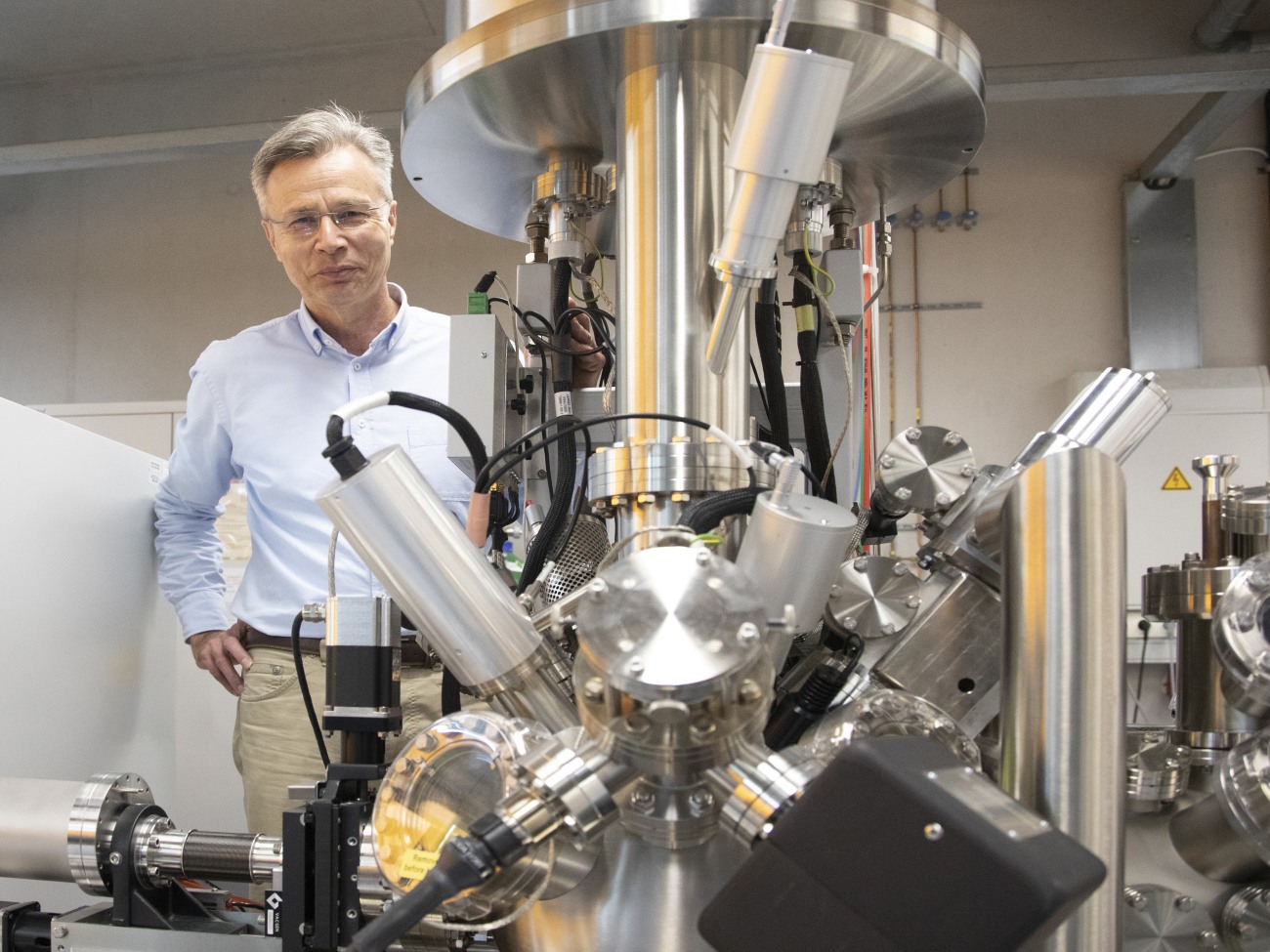

At the same time, the researchers are trying to improve the high-pressure process itself. For their experiments, they are using one of the few high-pressure furnaces available in Germany, located at ECOMAT, the Bremen Research and Technology Center for the Aerospace Industry.

© Jens Lehmkühler / U Bremen Research Alliance

A material’s strength, hardness, and elasticity are primarily affected by targeted heating and cooling. The material is subjected to different temperature ranges for varying lengths of time. “For example, we heated the high-pressure furnace at a rate of ten to 15 degrees Celsius per minute and cooled it at a rate of up to 1,600 degrees Celsius per minute,” says Altmann. Depending on the chosen temperature, this process can take several hours.

“We have achieved very promising results.”Mika Altmann

What can be achieved with the material that is created layer by layer during 3D printing? Where are the limits? Where do problems occur? What could potentially be critical? In a series of tests, the researchers produced material samples, determined their properties, and compared the characteristic values achieved in inert gas furnaces with those from the high-pressure process. Although the evaluation is not yet complete, Altmann already sees a clear trend. “We have achieved very promising results,” he says.

© Jens Lehmkühler / U Bremen Research Alliance

These include strengthing the components by 10 to 15 percent, making them significantly more resilient, while simultaneously using less material to achieve the desired properties. Ultimately, this reduces weight and thus fuel and costs, both in operation and in the manufacturing of the components. “In some cases, we no longer need the high-pressure process,” Altmann says happily. Even the process itself was improved.

Like the Leibniz-IWT, the Fraunhofer IFAM (Institute for Manufacturing Technology and Applied Materials Research) is also a member institution of the U Bremen Research Alliance and has been working on 3D printing. One issue they addressed specifically was making support structures easier to remove. These structures are necessary for complex components that are built up layer by layer to ensure stability during printing. “After printing, they have to be removed by hand, which is very time-consuming,” explains Dr. Stefan Dieckhoff, head of the Adhesion and Interface Research Department at Fraunhofer IFAM. The researchers have developed a solution that uses a pickling agent in combination with a predetermined breaking point created during printing.

© Jens Lehmkühler / U Bremen Research Alliance

Dieckhoff believes that two topics researched by the Fraunhofer IFAM as part of TIRIKA are even more important for the sustainability of aviation: environmentally friendly coatings and a new repair processfor the outer skin of aircraft. Researchers are working together to test materials and use materials science analyses to develop primers that protect against corrosion and will thereby protect the surfaces of aircraft components. These new primers are intended to replace previous chromate-containing products, which are potentially carcinogenic. “We have also identified more environmentally friendly sealant alternatives, since these are widely used in aircraft construction,” Diekhoff says.

“We have established relationships with prominent networks such as ECOMAT, the MAPEX Center for Materials and Processes, and the U Bremen Research Alliance.”Dr. Anastasiya Tönjes

The same applies to minor damage to the fuselage or wings, which can occur during handling on the ground. Many aircraft are made of carbon-reinforced plastic, a material that is difficult to repair. The researchers’ procedure first treats the edges of the damaged areas with a vacuum suction jet process. Adhesive technology is then used to coat the area with a repair patch that precisely replicates the original fiber directions and adapts aerodynamically to the surface. This repair method guarantees the repair will last for many years.

“The main appeal of TIRIKA lies in its diversity of topics. I have never seen an aviation research project of this scale and scope before,” says Dieckhoff, who has worked at IFAM since 1992. “TIRIKA is a flagship project in which many different disciplines collaborate with companies to research greater sustainability in aviation. That’s something really special,” Dr. Anastasiya Tönjes agrees.

For her, the project is also a testament to Bremen’s strength as a science hub, showcasing the expertise gathered in the city and the close cooperation among materials scientists and also other disciplines. “We have established relationships with prominent networks such as ECOMAT, the MAPEX Center for Materials and Processes, and the U Bremen Research Alliance. We have direct communication channels, which is often very helpful.”

© Jens Lehmkühler / U Bremen Research Alliance

The researchers pass their results on to industry, however, whether and when their work is implemented is not within their control. Researchers often need to be patient to see the effects of their work, especially in aviation. Testing procedures for innovations are strict, and safety standards are high. It can take many years for innovations to become established. But Tönjes is certain, “Our results will gradually be incorporated into production.”

ECOMAT: The Future of Aviation

Collaborative research between science and businesses under one roof – that is the basic idea behind the Centers for Eco-efficient Materials and Technologies located in Bremen’s Airport City. ECOMAT unites 500 researchers from various disciplines dedicated to topics related to net-zero aviation including new materials and the use of hydrogen. They share laboratory facilities and are united by the common goal of putting industry-related applications into practice as quickly as possible. Four member institutions of the U Bremen Research Alliance are involved in ECOMAT: the University of Bremen, the Leibniz Institute for Materials Engineering (IWT), the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), and the German Aerospace Center (DLR).

This article comes from Impact – The U Bremen Research Alliance science magazine

The University of Bremen and twelve non-university research institutes financed by the federal government cooperate within the U Bremen Research Alliance. The joint work spans across four high-profile areas literally from “the deep sea into space.” Biannually, Impact science magazine (in German) provides an exciting insight into the effects of cooperative research in Bremen.